Logistic Collaboration: A Strategy to Improve Hospital Efficiency and Health Quality in Mali

Abdramane Traore*

Department of Medicine, University of Bamako, Bamako, Mali

- *Corresponding Author:

- Abdramane Traore

Department of Medicine,

University of Bamako,

Bamako,

Mali,

Tel: 0022368806838;

E-mail: abdramane.traore@univ-nantes.fr

Received date: October 18, 2022, Manuscript No. IPJHMM-22-14675; Editor assigned date: October 21, 2022, PreQC No. IPJHMM-22-14675 (PQ); Reviewed date: November 07, 2022, QC No. IPJHMM-22-14675; Revised date: February 17, 2023, Manuscript No. IPJHMM-22-14675 (R); Published date: February 24, 2023, DOI: 10.36648/2471-9781.9.2.358

Citation: Traore A (2023) Logistic Collaboration: A Strategy to Improve Hospital Efficiency and Health Quality in Mali. J Hosp Med Manage Vol:9 No: 2

Abstract

This research investigates healthcare logistics issues in Mali. With the aims to understand, how logistic collaborations between partners can contribute to improve the quality of care. We used a qualitative method b ase on a deductive approach. The study was conducted by using semi-structure interviews. We also gathered several sources such as academic articles and key reports. The study finds that logistic collaborations can help reduce hospital costs, increase hospital efficiency and improve the quality of care. As the government of Mali is currently working on healthcare reforms, these findings can assist them to understand the crucial role of healthcare logistics.

Keywords

Quality of care; Healthcare logistics; Logistic collaboration; Hospital; Mali

Introduction

In most of African countries, there is an urgent need to reform the healthcare system. According to world health organisation, 8 million children under the age of 5 died in 2009, 74% were from poor countries [1]. The WHO also stresses out that every 30 second one child dies from malaria and almost 1500 women die during pregnancy or giving birth. We believe that all these deaths can be avoided if there is an appropriate healthcare system in place.

Materials and Methods

Context and challenges of the research

The problems of Africa healthcare systems are not only about resources and funding. It is mainly about the lack of infrastructure [2]. According to the director of the world health organisation, all the donated drugs in the world won’t do anything good without an infrastructure for their delivery. This statement indirectly puts the place of logistics at the heart of healthcare systems. Hospitals can be seen as an organisation where doctors and nurses are the engine and logistic activities the wagon. Without a strong logistics system in place it is difficult to run a hospital. In Mali, the need for skills has been pointed out as a major problem of the healthcare system [3]. But we strongly believe that the main causes of healthcare system dysfunction are due to poor organisation, lack of infrastructure and best practices in logistics and supply chain management.

Problematic of the research

The current drugs and medical materials supply chain network in Mali is not performing very well [4]. There is a very high level of drugs availability and out of date issues. So, in this case, we need to understand the logistic practices in hospitals but also to come out with a new model of supply chain organisation that is more efficient with a good collaboration between actors of the chain in order to improve the quality of care. In fact, some elements have been pointed out as major issues in Gabriel Toure hospital in the capital Bamako, which are:

• The need to reorganise the hospital supply chain network.

• A lack of competencies in healthcare logistics.

• The need to improve drugs distribution system.

• The need to improve the inventory management process in the hospital.

• Lack of collaboration between actors of logistic chain.

The question of our research is can collaboration between actors of healthcare supply chain network help to improve the quality of care in Mali’s hospitals?

Aims of the research

If more research has been conducted on the field of healthcare logistics in Africa, there is lit tle interest in logistics itself. In this perspective, our research will bring elements of understanding of the field of hospital logistics in Mali [5]. However, the main objective of the research is to propose a logistics model based on the collaboration of all actors in order to improve the quality of care within Gabriel Toure hospital.

The specific objectives are:

• To improve the stock management system.

• To improve the managerial practices of logistics within the hospital.

• To improve the quality of care.

• To improve patients’ satisfaction.

Theory choice and epistemological position

Logistic collaboration is viewed as a set of interenterprise relationships based on mutual trust, openness risks and benefits sharing. It is considered a source of competitive advantage for many organisations [6]. Collaborations can include many actors such as suppliers, distributors, transporters and Third-Party Logistics (3PL) etc.

The main concern about collaboration is how to preserve the individual interests and to work for the common interests.

Why should we collaborate?

Collaborations can concern many activities and functions in the organisation. For instance, it may include supply management, information technology and product distribution. Businesses or organisations decide to collaborate for many reasons [7]. Organisations collaborate because they want to have access to new technology, new market, to increase the product portfolio, to gain an economy of scale, to share risks, to acquire new competencies, to have financial and strategic advantages.

Healthcare logistics, what is it?

There are many definitions of healthcare logistics; we will present the most accepted definition in order to better understand the concept.

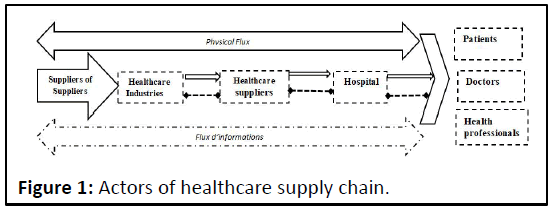

ASLOG defines healthcare logistics as the management of patient flows, products, materials, services and related information in order to ensure quality and safety at a defined level of performance and efficiency, from the provider to patient. It is the juncture of many supplies such as pharmaceutical products, medicine, clinical materials, office furniture and linens etc. (Figure 1).

In recent years, we have seen an acceleration of research and theories in logistics and supply chain management. Yet, there is very little research focused on the issues of hospital supply chain management.

In hospitals, logistic activities are the most important and perceptible at every stage of hospital value chain [8]. Supply chain activities in hospitals are multiple. For example, managing inventories, providing medicine and clinical materials, food and linens are part of hospital activities. It also includes the management of medical wastes. In fact management of medical wastes. In fact, logistics should not be seen as a simple operational function but as a strategic function in the hospital. So, in this context, the manager should not ignore the importance of logistic activities but to see them as strategic for the hospital. A dysfunction of logistic chain can have a very serious impact on hospital organisation. On the other hand, a very well organised and optimised logistic chain can be a source of efficiency but also could increase patients’ satisfaction and quality of care.

Many studies show the link between supply chain performance and quality of care. However, in the hospital, some issues such as availability, delivery time or mistake in ordering process can impact negatively the quality of care and patient satisfaction. Baratt argues that the phenomenon of collaboration is not new. At the very early stage of logistic development, companies were using Vendor Managed Inventory (VMI) and Continuous Replenishment Program (CRP) as a form of supply chain collaboration. The era of information technology and communication has facilitated the implementation of logistic collaboration [9]. But, some elements can make unsuccessful collaboration between trading partners and the failure to differentiate between partners to collaborate with. There are also some evidences that the lack of trust between partners can lead to the failure of collaboration. Some elements such as information sharing, mutuality benefit and risk sharing are the main reasons of collaboration.

However, providing pharmaceutical equipment and services to hospitals on a constant basis without stock outs or shortages is a challenge that requires the setting up of an efficient and effective logistics and supply chain system. From the 80’s-90’s, MRP systems were used in manufacturing industries, but now, has also been developed in hospitals given the complexity of material management, resource planning and the concern to improve the quality of care for the patient. Just In Time" (JIT) is an effective method of flow management but generally considered by some experts to be ineffective in hospitals supply chain management, given the unpredictability of emergencies. A drug or blood stock shortages can cause the death of patients. As a result, there is a real impact on the quality of care provided by the hospital. Several academic researches support the idea of a transposition of industrial methods and techniques on hospitals supply chain management in order to gain efficiency and effectiveness, but also to improve the quality of care for the patients. For some, "Lean management" can be very effective in hospitals supply chain management. Jobin and Sirjean, point out the lack of knowledge about supply chain management practices in hospitals. The aim of implementing an efficient logistics system is to create value for actors of the chain such as patients, doctors, hospital, distributors.

The notion of inter organizations collaborations is not a new concept in hospital management field. But research in logistic collaborations is in an embryonic phase. Collaboration in a logistic context may vary, depending of the individual or collective interests of logistic actors. This view point is shared by Pache and Spalanzani who believe that customers and suppliers relationships are complex and sometimes unstable and require a global approach of the whole supply chain by taking in consideration divergent and convergent interests.

Motives of logistic collaborations

Indeed, logistic collaborations can be motivated by the logic of pooling or sharing activities and the need to integrated logistics processes more efficiently. Collaborations ca n also be motivated by the need to exchange information and to reduce the logistics costs. For Barratt, the most important questions in logistic collaboration are with whom can we collaborate and on which activity should we collaborate?

The logistic constraints such as order execution speed, delivery time, the quality of service and costs reduction can structure the nature of the relations between the actors of the chain. In logistic collaboration, the different actors must learn together to build and manage a long term relationship in which they are mutually and sustainably involved. In this situation, actors (industrial, distributors and logistics service providers) should have a synchronized logistic operation in order to avoid stock outs and delivery delays. However, companies use logistics collaborations strategies to gain competitive advantages but also to reduce the transaction costs.

Types of logistic collaborations

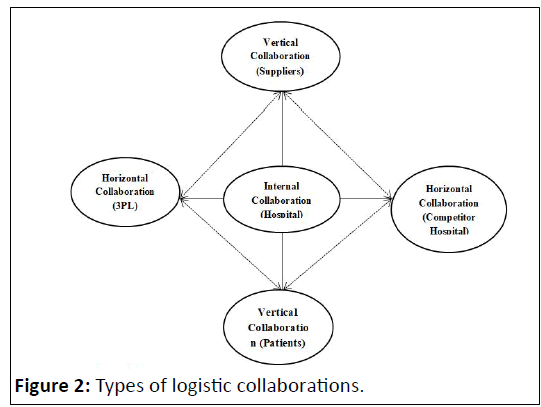

There are several types of logistic collaborations which are:

Vertical collaboration: Some of the most used are Vendor Managed Inventory (VMI), Collaborative Planning, Forecasting and Replenishment (CPFR). The VMI is a vertical collaboration between logistic actors and involves the establishment of close and iterative relationships. In the VMI system, the supplier delegates some or all of the management of its replenishments to some of its partners.

Horizontal collaboration: Compared to VMI or pooling supply chain is a form of horizontal collaboration in supply management. It involves the management of logistics chain by 3PL providers such as logistics platforms, transportation and information system.

Transversal collaboration: Generally, is the most flexible, it is the mixture of both types of collaborations (vertical and horizontal) in the logistic chain.

The advantages of logistic collaborations have been well documented in the literature. Collaboration can be factors of cost reduction, process optimization and amelioration of supply chain efficiency. It can also give a competitive advantage to the organization (Figure 2).

Key success factors of logistic collaborations

Actors in logistic chain decide to collaborate for many reasons, but what makes a successful logistic collaboration?

For Baratt, a collaborative culture is the key success factor of collaboration which is based on trust, mutuality, information sharing, openness and communication. Supply chain relationship is a constructive interaction between partners. For a successful collaboration, actors of logistic chain should have mutual trust and engage in a win-win strategy. Kwon, et al. stress that the lack of cooperation or collaboration between healthcare supply chain actors is a principal barrier for having an efficient and cost-effective process in the healthcare sector. After the literature review, we have adopted an interpretative approach with the plan to use 3 types of logistic collaboration as theory choices in order to explore and understand our case study. Healthcare expenses have increased over the years and more than 46% of hospital cost is linked to logistic activities. According to Mali government, healthcare ranked the second largest in state expenses after education.

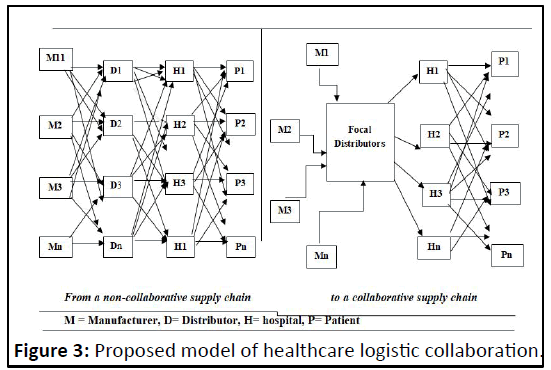

Our research uses logistic collaborations as theoretical model with the aims to understand its impact on healthcare quality and hospital performance. We explore hospitals logistic practices in Mali, through a qualitative method based on a deductive approach. To be able to have a full picture of logistic practices in hospitals, we used a semi-structure framework for our interviews as well as some academic articles and key reports. However, a case study has been considered as research strategy because it gives an insightful of actual practices within an organisation. It also has been advocated to be the appropriate strategy to understand complex issues in management (Figure 3).

Results

As this is an ongoing research, our proposed model is as follow:

The 1st approach is a non-collaborative supply chain of drugs and medical materials for the hospital. It shows a lack of cooperation between partners downstream of the supply chain. Every manufacturer passes through its own distributors to deliver drugs and medical materials to hospitals. This process can result in high prices for medicine, increase the cost of care and ultimately impact the quality of care and patient satisfaction. Studies show that drugs and medical materials represent 30% to 40% of an hospital expenses and can be reduced by at least 2% through improving the inventory and distribution processes. Drug shortage or out of stock can be critical for a hospital in giving a correct and effective care, in time to the patient.

The 2nd approach is a collaborative model that has some advantages for hospitals, distributors and pharmaceutical industries. The main advantage is the reduction of transportation cost for each of the actors of the supply chain, as the delivery process becomes more mutualized [10]. It reduces the delivery time and drugs shortage within hospitals. Increase the service quality for patients but for also both distributors and hospitals.

Research perspectives

This paper was intended to enhance the debates on supply chain collaboration in healthcare sector with a special emphasis on Mali healthcare supply chain network. Our study can be a trigger for finding some solutions to Africa’s healthcare logistics issues. We believe if successful logistics practices in manufacturing or retail is possible, it is also possible for the healthcare industry, even if there are major obstacles that need to be addressed. However, there is a very large area of further research in Mali healthcare logistics such as the role of information technology, lean management in hospitals, supply chain performance and patient flow management.

Discussion

The main difficulty was the choice of the theoretical approach in order to better understand the phenomenon. Our main goal is to explore, to understand and to propose some solutions to reorganise the logistic process for the hospitals. We are convinced that, as the research is going forward, we may face the reticence and the lack of collaboration of some employees and hospital directors.

Conclusion

Logistic activities are central and very important in the hospital. Failure to manage them efficiently and effectively will certainly result in a poor quality of care but also in patient dissatisfaction. Yet, there is an urgent need to reorganise the health care system in some African countries. We can witness everyday a collapsing and chaotic healthcare system in Africa due to the need of value resources and competences but also of poor management. Many researches advocate the benefits of collaboration between organisations. Supply chain collaboration, if very well defined, can improve the healthcare performance.

Authors mention some barriers to a successful supply chain collaboration, such as lack of trust between partners, commitment and willingness to engage the necessary resource if needed. Most of the failure of supply chain collaboration is the result of lack of good understanding between partners of what exactly collaboration means and involves.

To finish, healthcare logistic collaboration can contribute to improve hospital efficiency and reduce the supply chain cost. It can also ameliorate the level of service quality and increase patient satisfaction.

References

- Abbad H (2014) Pooled supply management: Myth or reality? Int J Logist Manag 2:41-50

- Babei J, Pache G (2015) Creating value for the customer in an SCM context The case of the distribution of pharmaceutical products in Cameroon. J Manag Sci 275276:173-182

- Baratt M (2004) Understanding the meaning of collaboration in the supply chain. Int J Supply Chain Manag 9:30-42

- Beaulieu M, Landry S (2002) How to manage hospital logistics? Two countries, two realities. Management 27:91-98

- Beaulieu M, Roy J (2015) Benchmarking of purchasing and inventory management in hospitals: A Canadian approach. Int J Logist Manag 23:17-27

- Bonet D, Pache G (2005) A new approach for understanding hindrances to collaborative practices in logistics channels. Int J Retail Distrib Manag 33:583-596

- Camman C, Monnet M, Guieu G, Livolsi L (2013) The strategies of actors in logistics pooling. What is at stake in logistics pooling? Int J Logist Manag 21:57-73

- Ergun O, Kuyzu G, Savelsbergh M (2007) Shipper collaboration. Comput Oper Res 34:1551-1560

- Audy JF, Lehoux N, D'Amours S, Ronnqvist M (2012) A framework for an efficient implementation of logistics collaborations. Int Trans Oper Res 19:633-657

- Daudi M, Hauge JB, Thoben KD (2016) Behavioral factors influencing partner trust in logistics collaboration: A review. Logist Res 9:1-9

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences